Products

NEW PRODUCTS

Products

NEW PRODUCTS- CROSSOVER GANYMEDE

- CROSSOVER ANTIQUE PINK

- SERENITE

- NEW DAMA

- NEW SWIVEL

- NEW SWORD DB-20/DB-21

- Stephen Moody Competition Winning II

- NEW GURU

- 2024 ENGRAVING MODEL

FEATURED PRODUCTSCUT SCISSORSTHINNING SCISSORSOTHERSSERIES 360ºMIZUTANI

NEWSEDU SEMINARMOYO ShowroomSUPPORT

360ºMIZUTANI

NEWSEDU SEMINARMOYO ShowroomSUPPORT

TOP > Nano Powder Metal

Ultimate sharpness and

Long-cutting life

to bring out

the best performance

Ultimate sharpness and Long-cutting life

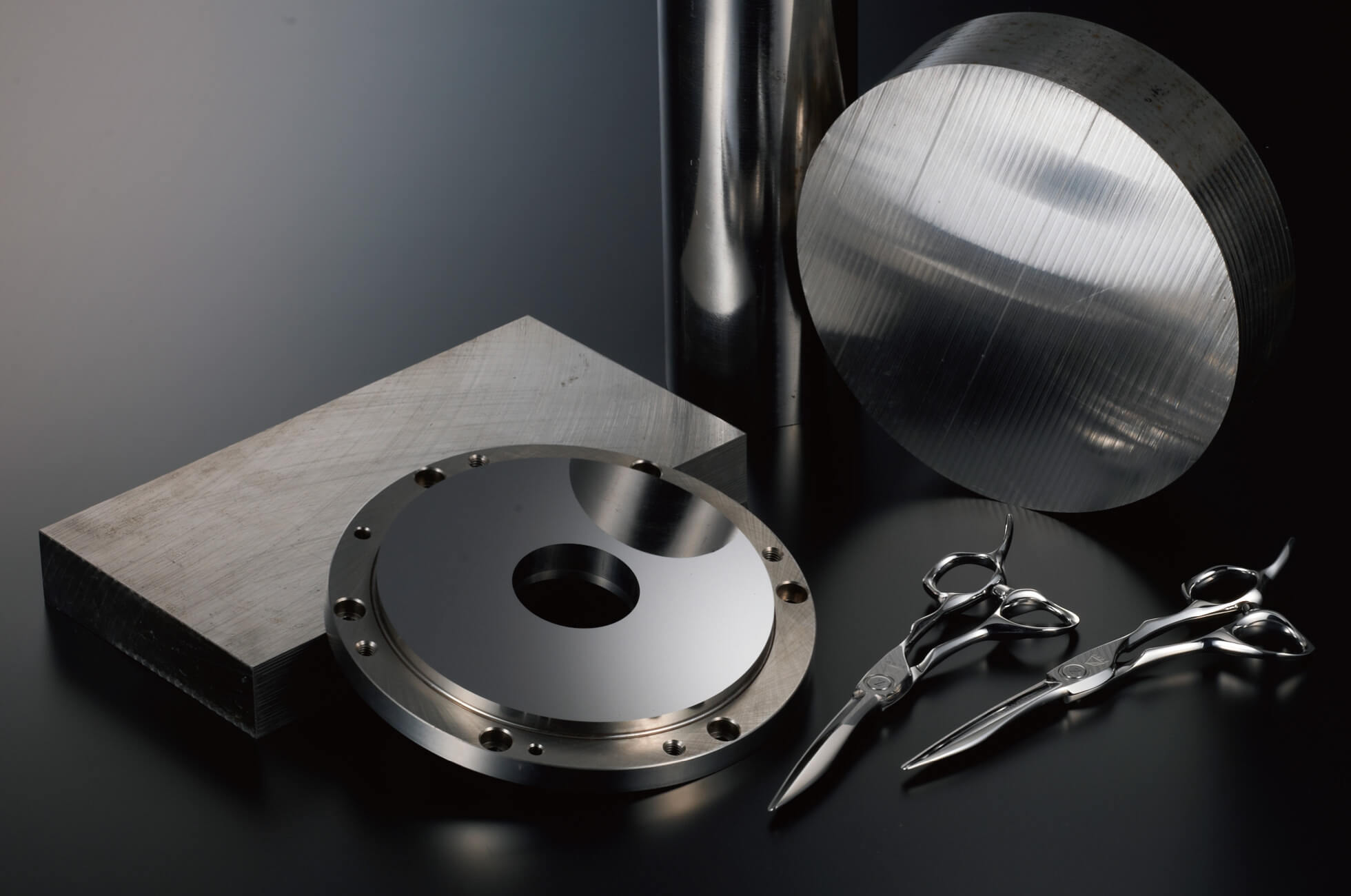

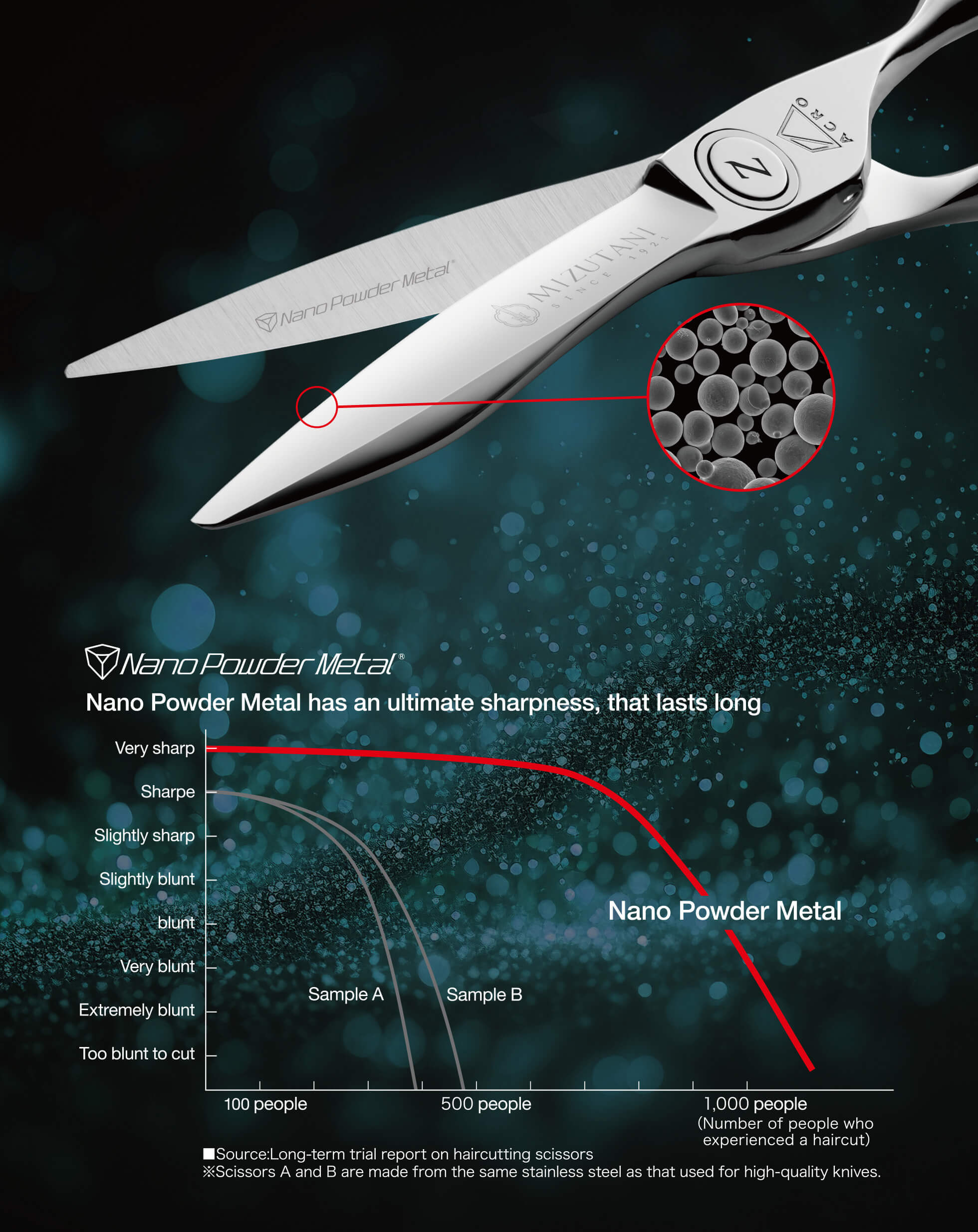

The sharpness and durability of scissors are important factors that are directly linked to hair cutting performance. Sharp scissors allow you to cut hair accurately without damaging it, which also effects the finish. Durable scissors can be used for a long time. MIZUTANI’s Nano Powder Metal is an innovative material that pursues sharpness and durability.

For you a amazing and impressive cutting experience

You can experience a new sensation of cutting with an unbelievable sharpness. While experiencing the joy of cutting, you will be surprised at how much faster your work will be.

Dr. Kentaro Asakura, Engineering Department of Materials Engineering

at the School of Engineering, The University of Tokyo(Part-time instructor)

at the School of Engineering, The University of Tokyo(Part-time instructor)

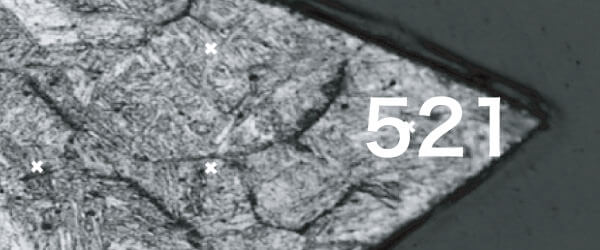

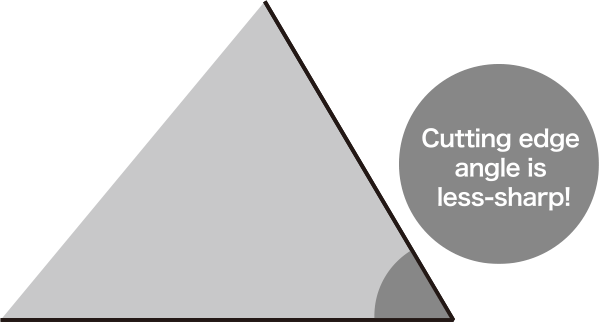

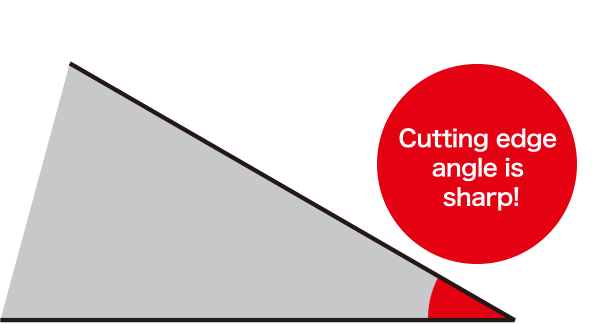

Angle and the shape of the cutting edge of the Nano Powder Metal

The sharpest cutting edge angle doesn’t require much grip strength for cutting hair since it easily dig into hair.

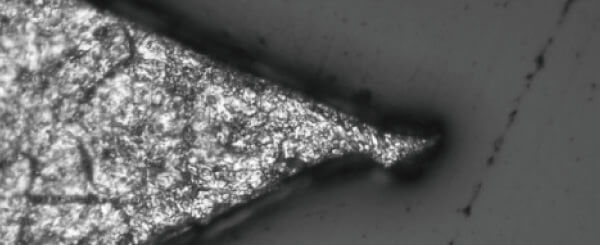

Other maker

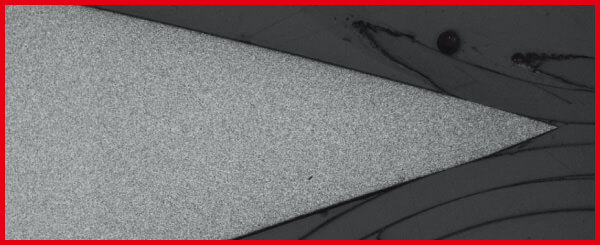

Nano Powder Metal

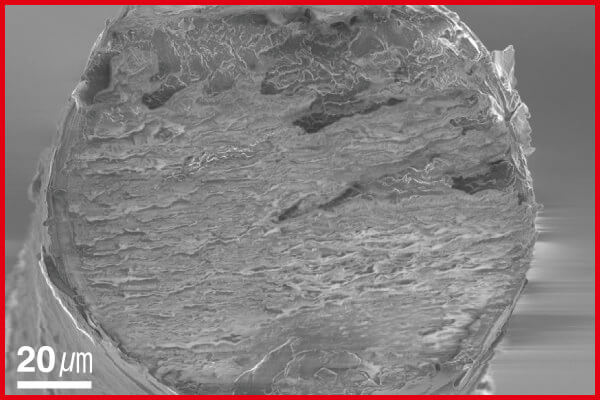

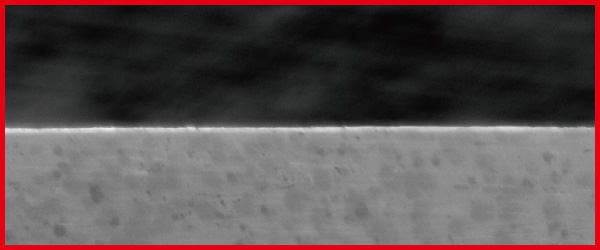

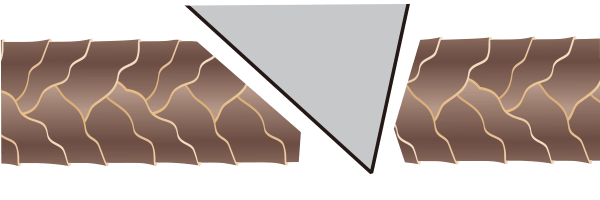

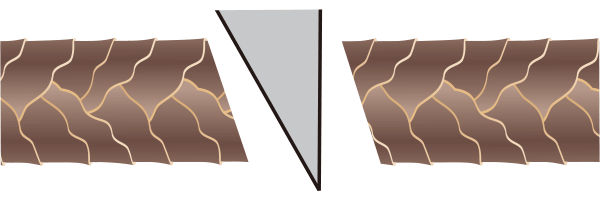

Cross-section of hair cut by Nano Powder Metal

Sharp cutting edge of Nano Powder Metal gives no hair damaged.

It prevents damages like split hair ends as much as possible.

It prevents damages like split hair ends as much as possible.

Other maker

Nano Powder Metal

Nano Powder Metal was properly heat treated to obtain enough hardness all the way to the tips of blade.

*A greater Vickers hardness value means harder blades.

Hardness of other maker

Hardness of Nano Powder Metal

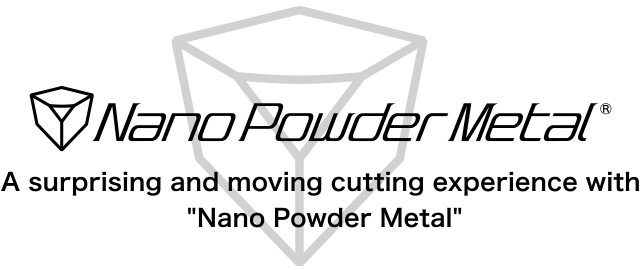

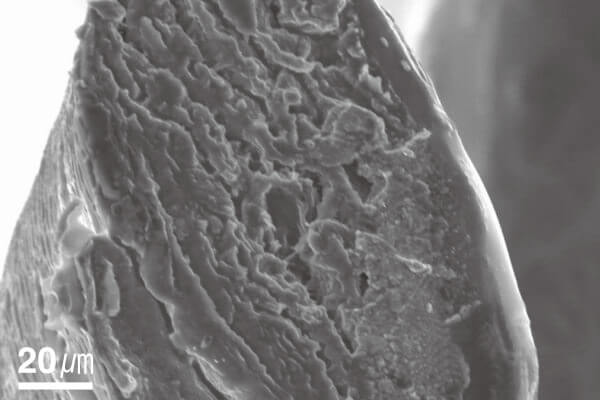

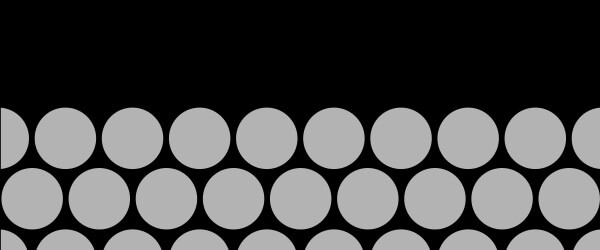

Nano Powder Metal blades having fine particles like powder, can prevent making large chips.

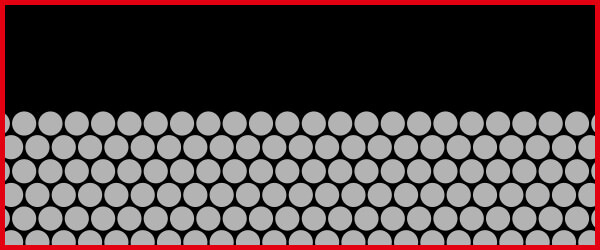

Particle of other maker (*image)

Particle of Nano Powder Metal (*image)

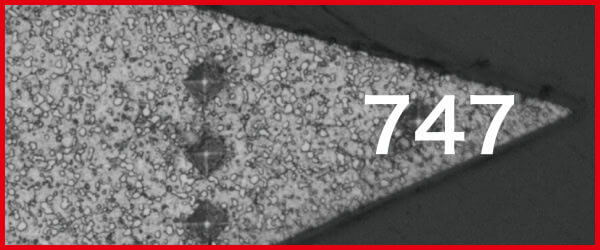

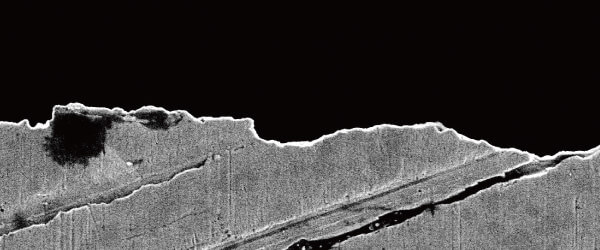

Side of blade tips of other maker

It shows the linear scratches and jagged edges that are commonly seen on blades with a rough uneven edge.

Side of blade tips of Nano Powder Metal

It proves the blades are smooth enough to have almost no nicks or scratches.

The sharp cutting edge angle of Nano Powder Metal, achieve sharp and stress-free cut.

The cutting edge angle of conventional haircutting scissors is between 40-80°

The cutting edge angle of

ACRO Z is 30-35°

The less-sharp cutting edge angle makes hair damaged since it is cut in a way that mashed.

The sharp cutting edge angle achieve sharp and stress-free cut

The point of Nano Powder Metal is how to properly heat treat it. Appropriate heat treatment creates a uniform and fine structure, allowing for strong and sharp edges. Another greatest point is its high durability as material.