ACRO Z-2

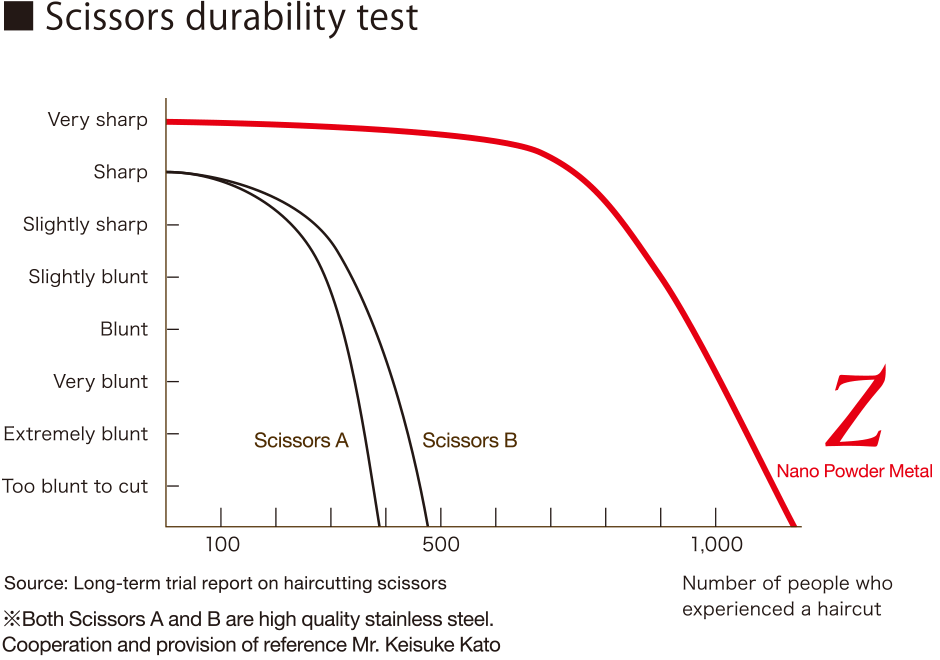

"ACRO Z Nano Powder Metal," scientifically proven to have durability and to not damage hair. With unprecedented sharp blades, these shears bite into the hair, grasp the hairs you aim for, and do not let them go, right to the corner of the panel.

Size : 5.5INCH6.0INCH6.5INCH7.0INCH

Use : BLUNT

Material : Nano Powder Metal

5.5INCHBlade length : 55mm

[Bottom blade] Ring size:horizontally/18mm・vertically/20mm

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103073

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103073

6.0INCHBlade length : 62mm

[Bottom blade] Ring size:horizontally/18mm・vertically/20mm

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103074

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103074

6.5INCHBlade length : 72.7mm

[Bottom blade] Ring size:horizontally/18mm・vertically/20mm

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103075

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103075

7.0INCHBlade length : 82mm

[Bottom blade] Ring size:horizontally/18mm・vertically/20mm

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103076

[Top blade] Ring size:horizontally/17mm・vertically/20mm

Product number : #103076

The potential of “Nano Powder Metal”

It is commonly known that many women experience the nagging problem of split ends. This begs the question: What if it’s our scissors that is causing this problem? Asking ourselves this question motivated Mizutani’s product development team to gain a better understanding of hair when it is being cut using scissors.

First, we examined actual hair to elucidate the mechanisms of cutting it with scissors. Eventually, we started to ponder an idea: “Is there any way that scissors can create a clear-cut cross-section without damaging hair?” The key words here were “cutting edge angle,” “hardness,” and “materials,” regarding the blade. We then found, as the examination proceeded, that a “cutting edge angle that makes it easy to cut into hair” is essential for creating an excellent haircut. If the blades of conventional scissors, however, are sharpened too much, they cannot hold their edge well and become easily blunt. Under this tough condition, Mizutani came up with a material now known as “Nano Powder Metal” (NPM), which is produced using a special manufacturing process called HIP (Hot Isostatic Pressing). This nano-scale fine powder steel is made by fusing uniform particles at high temperature and pressure, thus it has extremely low impurity and inclusion levels. Currently, this material property is applied to manufacturing high-precision industrial equipment that is required to be impurity-free, such as Blu-ray disc molds (photo, right).

Our new haircutting scissors, the ACRO Z, has been developed making strong use of Nano Powder Metal (NPM) made from uniform fine particles. Making a sharp cutting edge possible, we are proud to present a product that can dramatically reduce split ends, while also exhibiting great durability and hair-friendliness.

First, we examined actual hair to elucidate the mechanisms of cutting it with scissors. Eventually, we started to ponder an idea: “Is there any way that scissors can create a clear-cut cross-section without damaging hair?” The key words here were “cutting edge angle,” “hardness,” and “materials,” regarding the blade. We then found, as the examination proceeded, that a “cutting edge angle that makes it easy to cut into hair” is essential for creating an excellent haircut. If the blades of conventional scissors, however, are sharpened too much, they cannot hold their edge well and become easily blunt. Under this tough condition, Mizutani came up with a material now known as “Nano Powder Metal” (NPM), which is produced using a special manufacturing process called HIP (Hot Isostatic Pressing). This nano-scale fine powder steel is made by fusing uniform particles at high temperature and pressure, thus it has extremely low impurity and inclusion levels. Currently, this material property is applied to manufacturing high-precision industrial equipment that is required to be impurity-free, such as Blu-ray disc molds (photo, right).

Our new haircutting scissors, the ACRO Z, has been developed making strong use of Nano Powder Metal (NPM) made from uniform fine particles. Making a sharp cutting edge possible, we are proud to present a product that can dramatically reduce split ends, while also exhibiting great durability and hair-friendliness.

- Nano Powder Metal

Our Nano Powder Metal®, made with the new HIP manufacturing method (Hot Isostatic Pressing), is steel fabricated from a fine powder at the nano level. The uniform-grained powder is hardened with high temperature and pressure tempering, essentially eliminating all filler and impurities, and this method is used in precision manufacturing items like Blu-ray disc molds, where high levels of purity are required. At MIZUTANI, in order to create the ideal hair-cutting scissors, we have conducted our own proprietary research with this material, and created scissors with blades that combine strength with a long cutting life and the ultimate sharpness.

- BALL BEARING

These metal ball bearings are small, high precision items produced by a Japanese manufacturer. With superior anti-rust properties compared to foreign-made products, they have a high level of durability. By drastically reducing friction around the screws, they not only ensure smooth opening and closing of the scissors, lessening burdens on the hands, but also protect the edge from damage, contributing to long cutting life.

- ORGANIC DESIGN

The handles are so designed that they look nonmetallic, alive and organic. You may feel some warmth from the three-dimensional, twisted handles, and once touched, you would not like to part them from your hand.

- DISK DRIVER

Compact and easy to turn, this is a flat type driver for UFO screws. This screwdriver is included with all scissors with the mark shown.

* ACRO® is registered trademark of MIZUTANI SCISSORS in Japan.

※ is registered trademark of MIZUTANI SCISSORS in Japan.

is registered trademark of MIZUTANI SCISSORS in Japan.

※